联系我们Today!|(262)784-3340

At Anderson Process, we’re determined to earn your business through integrity, trust, expertise and knowledge.This unique customer focus drives our core mission: to enhance the operational profitability of each of our customers by providing expert-driven fluid equipment integration and services that increase production output, reduce maintenance costs and drive efficiency.

Through close collaboration with our customers, we strive to add value in ways that simple warehouse suppliers can’t, without the impractical costs and processes associated with full systems engineering firms.

我们广泛的流体工艺设备目录,包括领先的工业泵,经过NAHAD认证的软管组件,最先进的滤清器技术以及一组广泛的支持设备,使我们能够通过最佳解决方案解决专业挑战。无论是通过我们的综合产品线,还是通过我们增值的咨询,产品规范协助和售后服务,我们都会提供人员和所需的产品,以帮助您定义和实施应用程序的理想集成流体处理解决方案。

The Anderson Process commitment to service and support makes us true “solutions integrators” in every sense of the term.这意味着我们不仅要接受设备订单。我们进行了额外的工作,以了解您的操作的具体细微差别,并利用我们所有的资源来帮助您充分利用自己的资源。

Through hands-on direct collaboration, our team works closely with each of our customers to come to a 360-degree, in-depth understanding of their fluid-handling processes and challenges. Once this is achieved, we leverage our expertise to recommend the best possible equipment and system integration that optimizes your process and increases plant profitability.

从那里开始,我们的增值服务组合有助于确保您的运营能够以峰值的效率可持续运行 - 有效地创建了一个“集成解决方案”软件包,您可以依靠,以最大程度地提高流体管理投资。

With thousands of industrial pumps on the market, and numerous configurations available for each of those pumps, choosing the right pump system can mean the difference between profit and loss. Anderson Process’s in-house engineers are experts in fluid dynamics. The process pumps we specify — whether it be a multistage centrifugal pump for high-pressure water pumping or a diaphragm pump for moving high-viscosity slurries — will be the ideal type and size for even the most demanding applications. Our brands — including Wilden®,Graco和Gusher Pumps - 以其创新和可靠的性能而闻名。

从最大的产品恢复和材料兼容性到紧密的设备足迹和高压排放功能,Anderson Process的泵提供了最佳的流体转移功能,可最大程度地提高操作的输出。作为许多品牌的授权服务中心,安德森流程的专家维护服务将确保您的工业泵具有较长的使用寿命。

安德森(Anderson)流程了解安全可靠的软管组件和软管配件为制造业和工业运营带来的价值。使用不兼容或劣等软管不仅对操作员,而且对盈利能力都是危险的。Anderson Process提供了一系列Nahad认证的软管组件,这些软管组件具有可靠的安全性和可靠性记录。

Offering a broad range of materials compatibility — from corrosive chemicals and petrochemicals to high-pressure, high-volume water and food products — our line of hoses include composite, hydraulic, industrial, Teflon®和金属软管。还提供了可信赖的制造商(例如Novaflex,Dixon和Continental)的耦合,适配器,扩展关节和其他配件的广泛清单。Anderson Process很荣幸提供创新的维护跟踪和翻新计划,不仅可以简化软管维护,而且可以提高植物安全性。

Filters and strainers enhance the reliability of hydraulic and lubrication systems by removing a wide range of particulates. As a result, quality filtration components are a critical aspect of a processing line that is optimized for maximum productivity. Poorly filtered fluids are one of the leading causes of premature wear and failure in a fluid process system. Anderson Process’s filtration line, which includes housings, vessels, filter bags and filter cartridges, help ensure that industrial and manufacturing processing equipment achieves maximum life and uptime. With Anderson Process’s maintenance and replacement scheduling assistance, operators can rest easy that unexpected shutdowns will be minimized and product quality will be maintained.

As a provider of “integrated solutions,” Anderson Process is proud to provide custom skids that efficiently solve the challenges most frequently experienced in today’s manufacturing and industrial processing applications. Familiar with common process problems that “off-the-shelf” systems simply can’t handle, Anderson Process’s team of expert engineers and technicians collaborate to design and fabricate turnkey process skid systems that directly address issues unique to specific processing applications.

From portable mixing skids and pump skids, to transfer skids and industrial chemical feed skids, Anderson Process’s engineers develop skid designs that are constructed with serviceability and equipment footprints in mind. Our skid development services leverage components from trusted equipment manufacturers to ensure both efficiency and production output are maximized to the fullest extent.

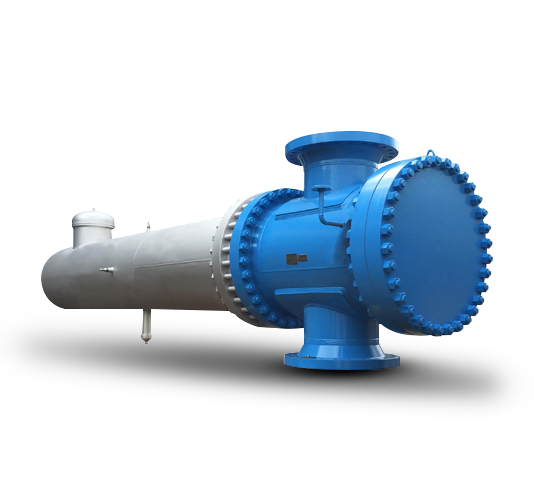

液体处理中的过程温度管理在逻辑上很复杂。废热恢复是工业和制造运营最有效的方法之一,不仅可以减少运营费用,而且可以帮助提供一致的产品质量。

Anderson Process提供了一系列的废热恢复设备,包括来自标准Xchange等最受信任的传热技术制造商,包括板和框架热交换器和管状热交换器。Anderson Process的废热恢复工具为各种操作条件(包括极端温度和压力,紧密的空间或具有挑战性的材料)而设计,可提供一致的长期性能,可促进效率和生产产量,同时最大程度地减少维护需求。

不足或无效的混合可能会导致不一致的质量,产品损失,甚至导致卫生处理和工业制造应用中的交付。安德森(Anderson)流程的设备专家已经掌握了流体动力学科学,以确保安德森(Anderson)流程指定的混音器将提供一致,可靠和有效的性能。

我们的搅拌机由两家领先的搅拌机制造商(Sharpe Mixers和Hayward Gordon)提供,可提供一致的混合,最少的维护和最大的正常运行时间。从重型工业搅拌机需要高扭矩的高粘度流体,到对可清洁度进行优化的卫生搅拌机,安德森工艺的混合器都是由耐用的组件构建的,这些组件可防止停机时间并提供批处理到批量的一致性。